Engineering simulation

Minimization of Full-Scale Testing

Expansion of available options to choose

Selection of optimal product's design

Digitalization of the project development process

Solutions by industry

Comprehensive approach

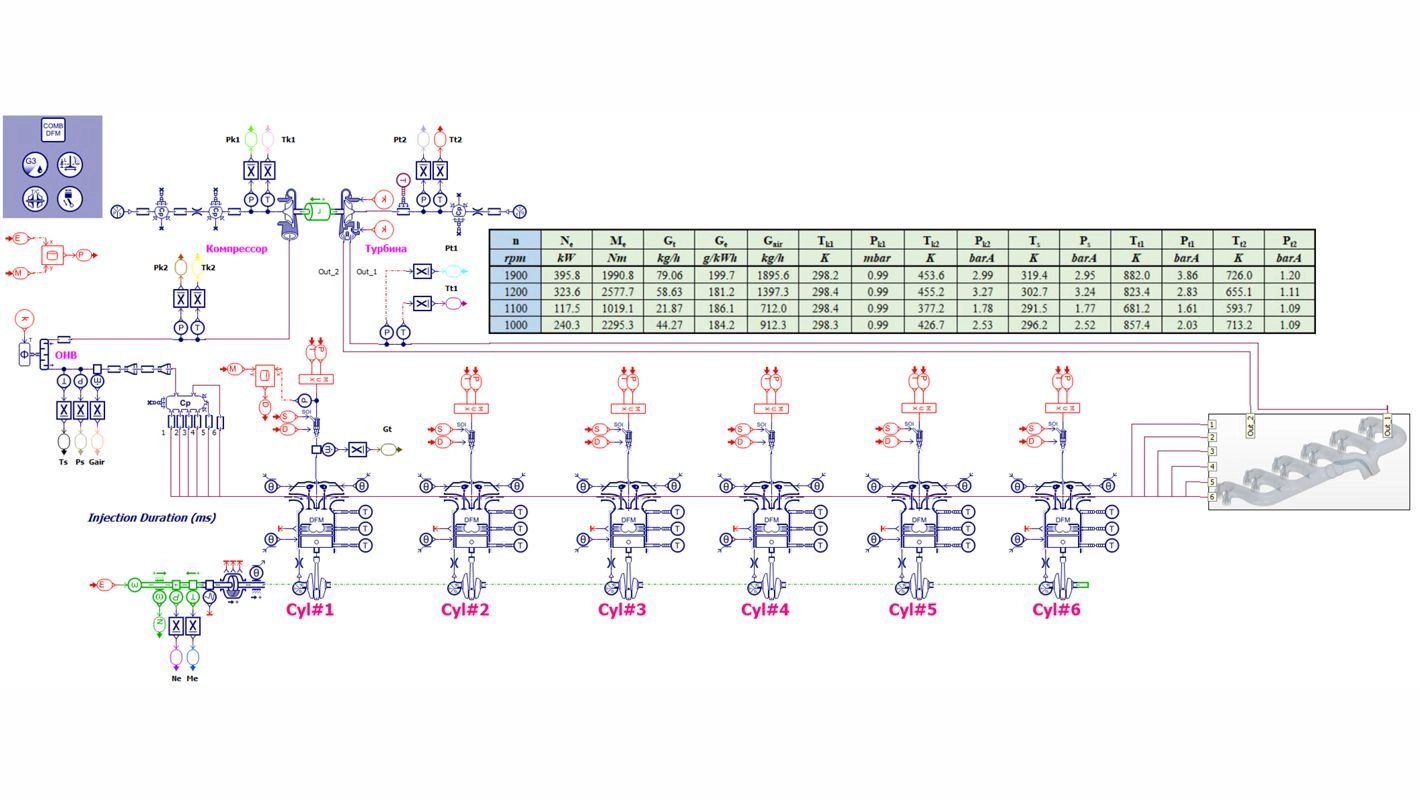

Systems engineering and high-level architecture

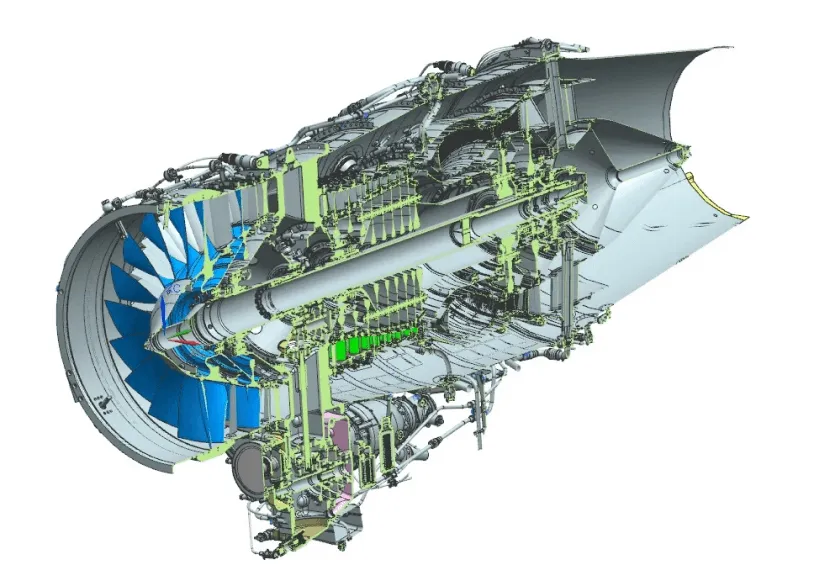

Strength and Aerohydrodynamic Calculations

Methodology development and processes optimization

Digital twin

Portfolio

Our projects

Resources

Unique competencies

Application areas

Disciplines

System engineering

( 01 )Construction of automatic settlement chains

( 02 )Reverse engineering

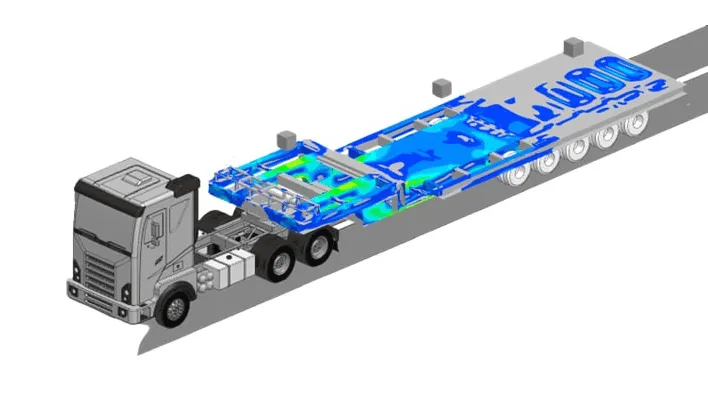

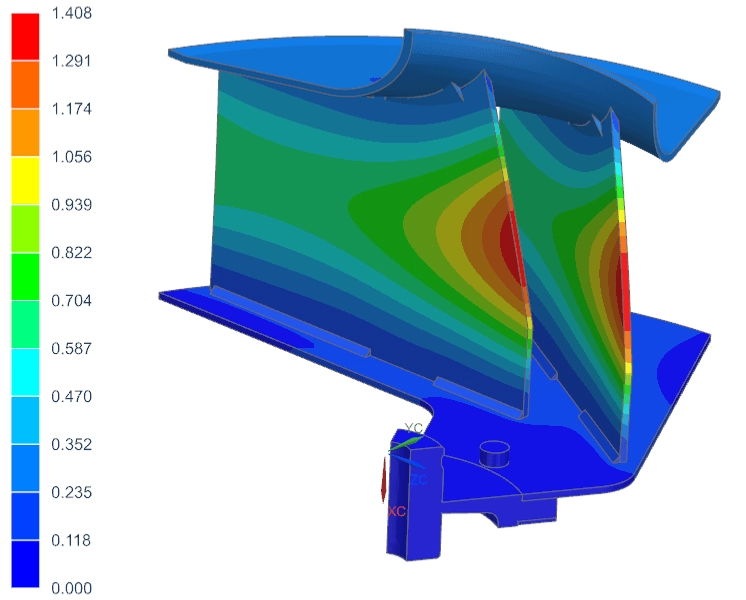

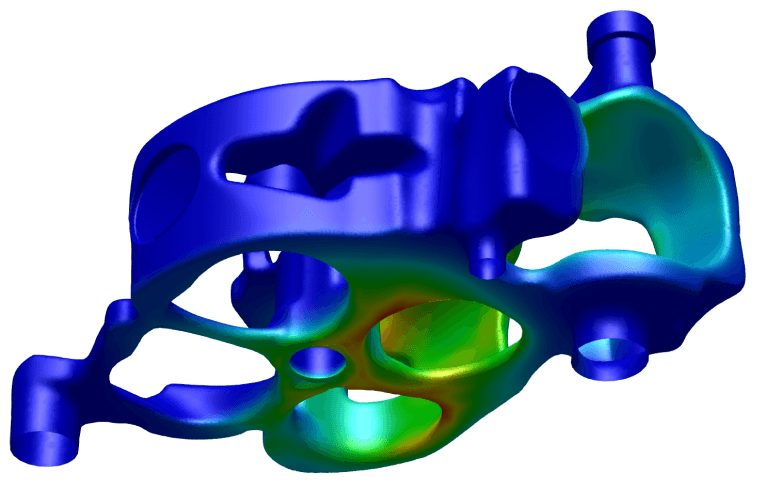

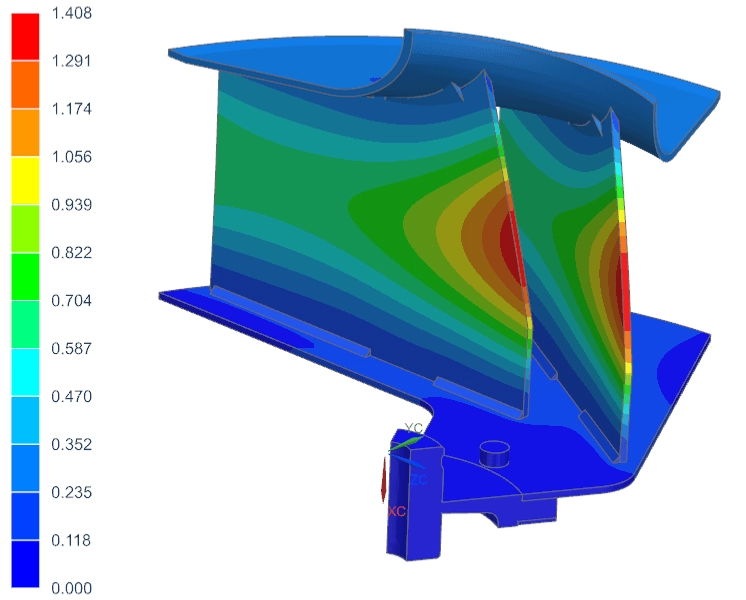

( 03 )Strength and stability calculations

( 04 )Fracture mechanics

( 05 )Calculation of product durability

( 06 )Crack resistance

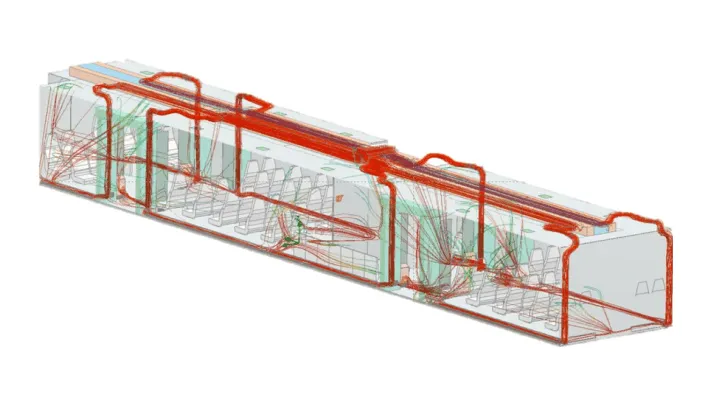

( 07 )Aerodynamics and hydraulics

( 08 )Multiphase flows and combustion

( 09 )Thermophysics

( 10 )Calculations of electromechanical and electronic devices

( 11 )Modeling of high frequency electronic products

( 12 )Connected interdisciplinary analysis

( 13 )Vibroacoustics and acoustics

( 14 )Parametric and topological optimization

( 15 )Functional safety assessment and reliability calculation

( 16 )

Contact Us

Free consultation

Tell us about your challenges and we will provide you with a solution!