Reverse engineering

Compliance with requirements

Shortening the development cycle

Improving technical characteristics

Solutions by industry

We guarantee the accuracy, compatibility, and performance of your reverse-engineered components through a multi-phase prototyping process, in-house testing, and a tailored gated approach

Recovery of design documentation

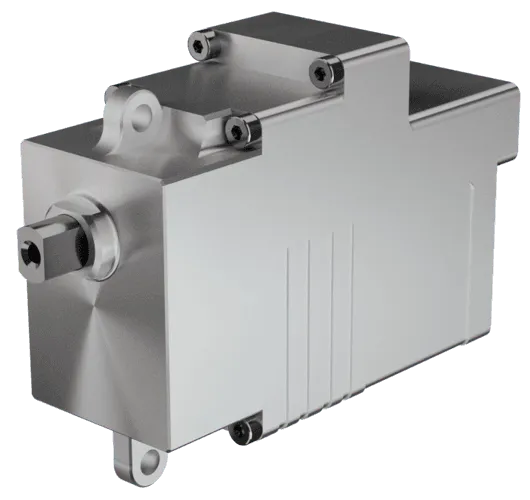

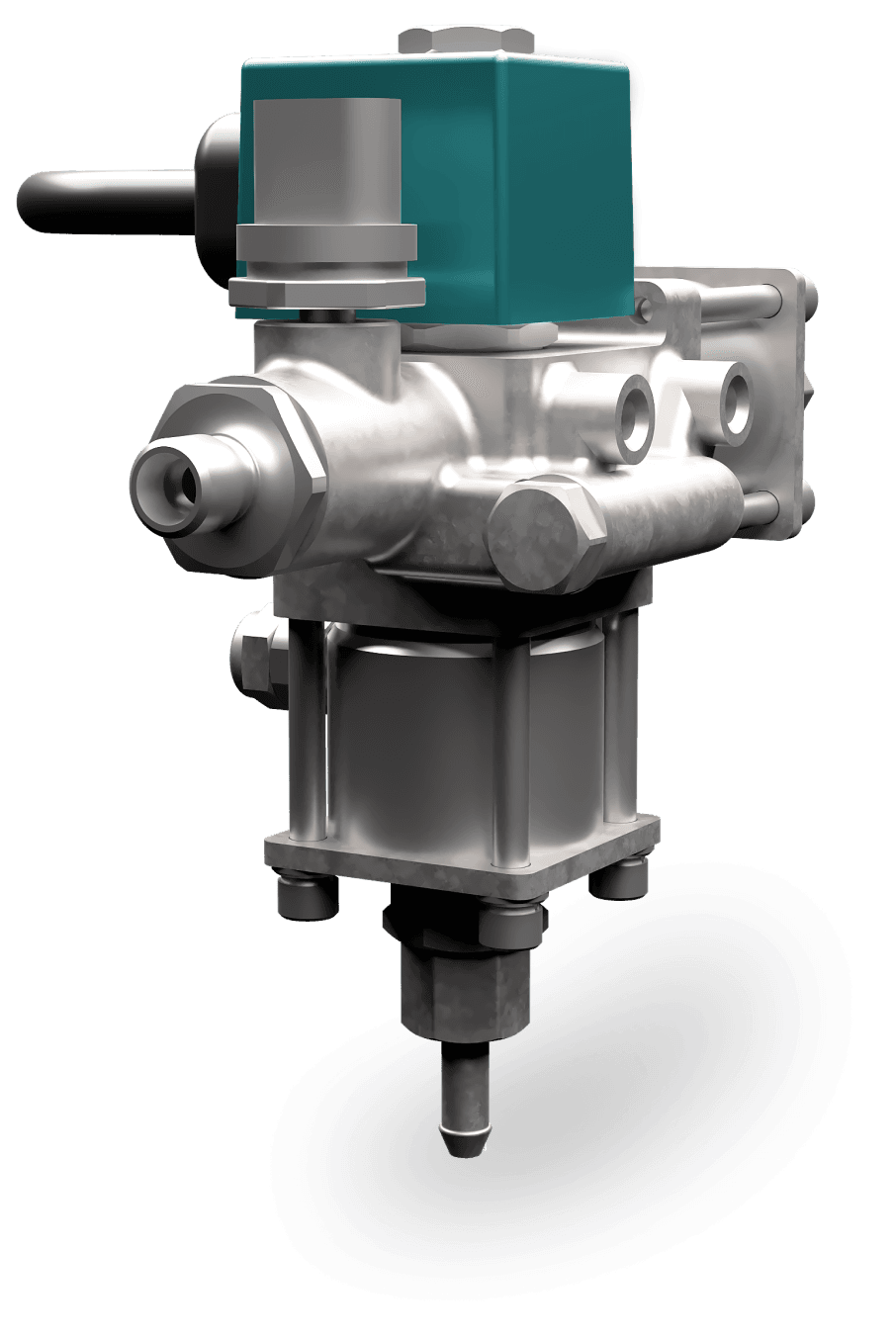

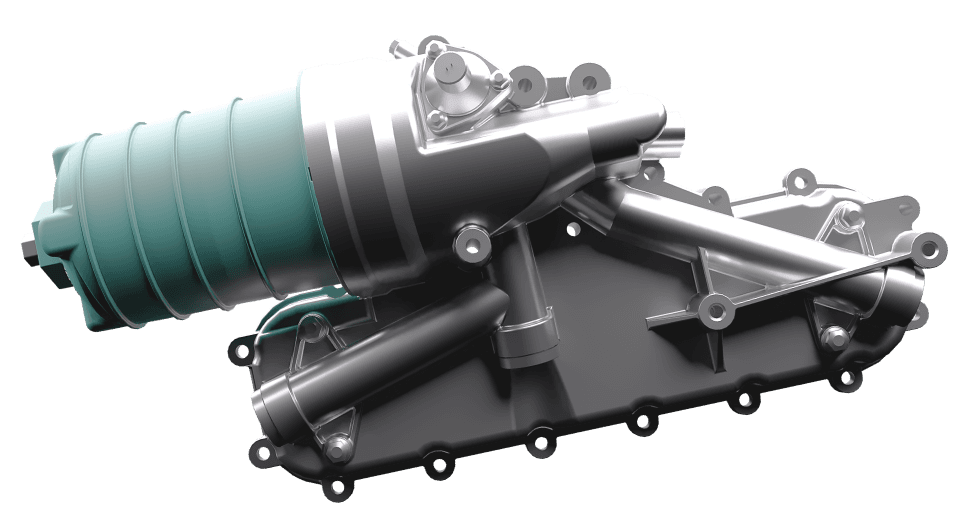

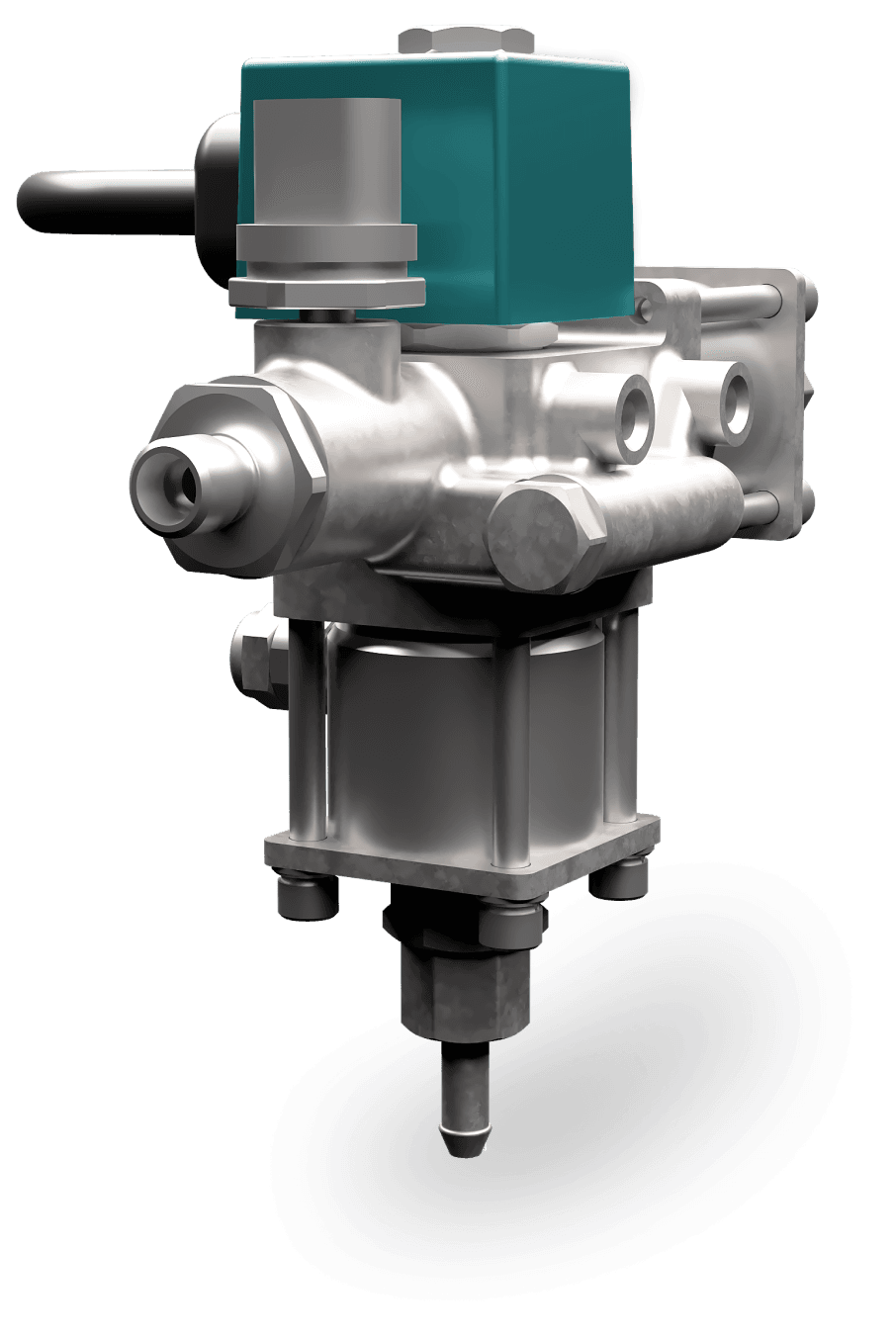

Production of components

Replacement of defective parts

Our projects

Our projects

Products

Products

All stages of reverse engineering

Full cycle from demand to production

- 1

Preparation for 3D scanning

Disassembling the product into components - 2

3D scanning

We thoroughly scan the product to obtain data for a 3D model - 3

3D modeling

Transforming a point cloud into a polygonal 3D model - 4

Sample exploration

Our engineers team identify materials and select high-quality domestic alternatives - 5

System engineering

We carefully design the product architecture while considering the environment and defining product requirements - 6

Engineering simulation

Validation of the necessary product specifications - 7

Design documentation

We undertake preparation of all necessary for production documentation - 8

Production technology

We apply all of our expertise to select the optimal production methods considering the available equipment - 9

Prototyping and testing

Creation of a prototype for testing and validation of component performance

Capabilities

New equipment

Laboratory study of materials' chemical composition

( 01 )Tests of prototypes

( 02 )3D scanning and 3D geometry control

( 03 )Additive and laser technologies

( 04 )CNC miling and turning

( 05 )Production of polymer and composite materials

( 06 )Sheet metal fabrication

( 07 )Foundry

( 08 )Heat treatment

( 09 )Quality control

( 10 )

In-house production

Photos

Contact Us

Free consultation

Learn more about the power of reverse engineering in designing your product